Blog

Exploring Artificial Quartz Stone: Composition and Advantages

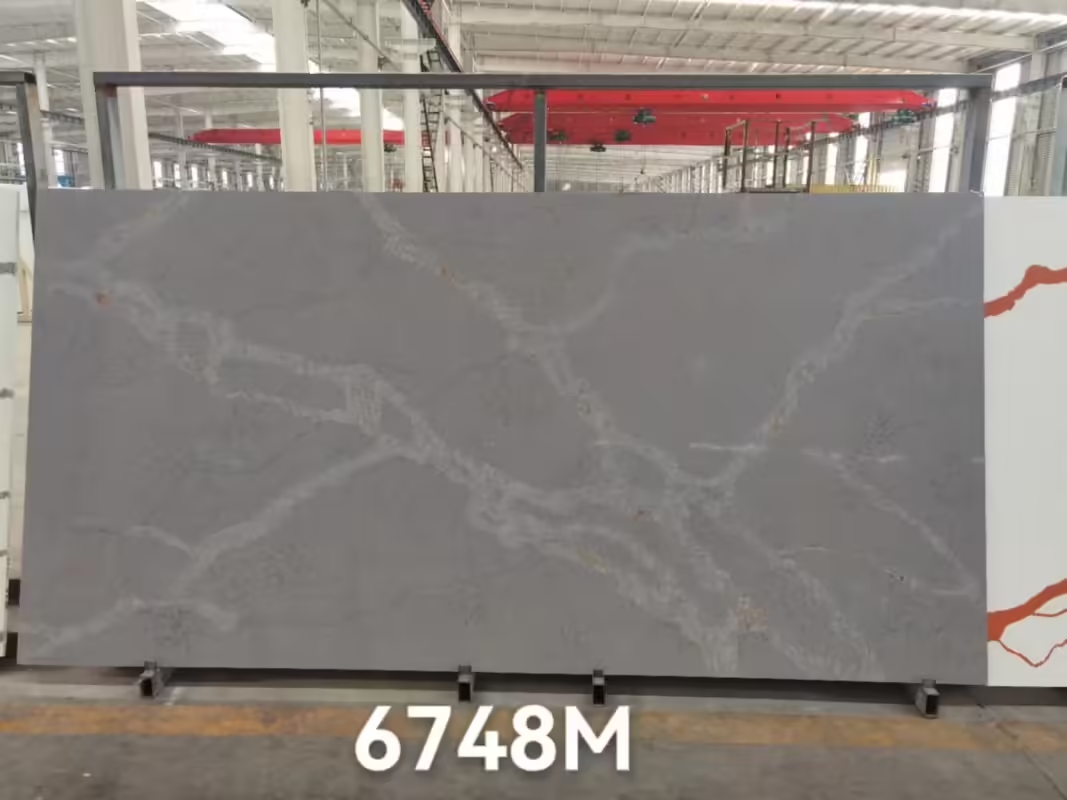

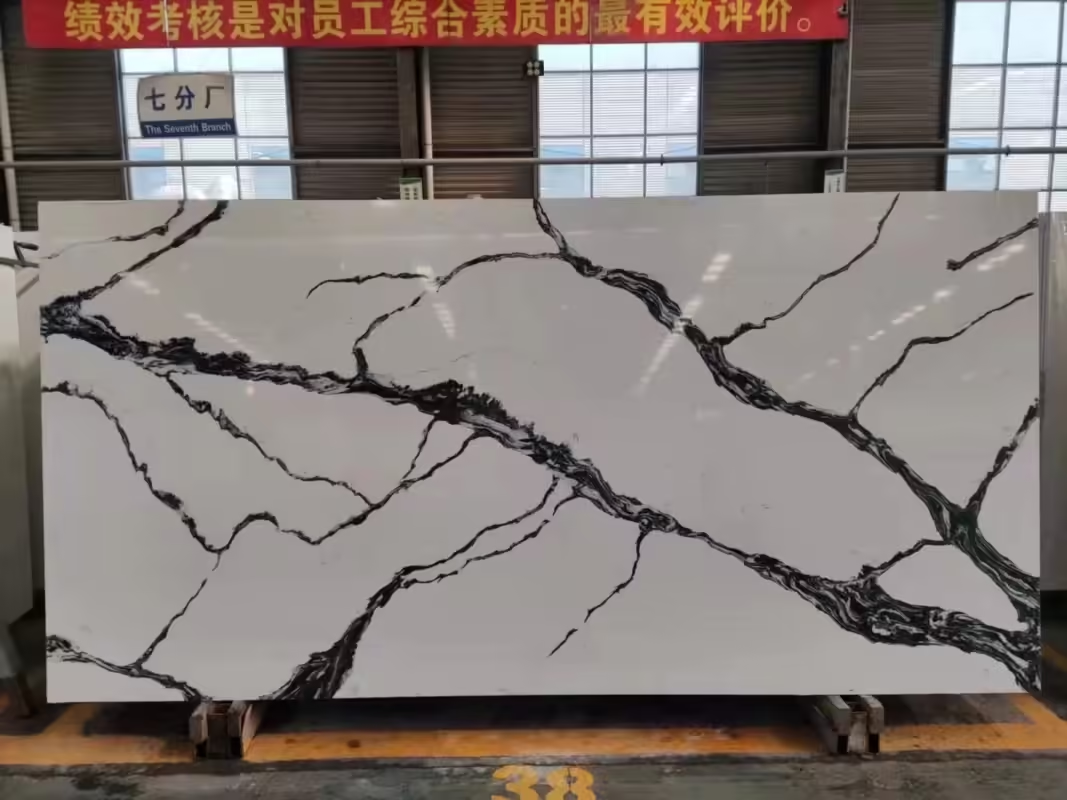

Artificial quartz stone is a composite material known for its durability and aesthetic appeal, making it a popular choice in both residential and commercial design projects. This engineered stone is primarily made from natural quartz, one of the hardest minerals on Earth, which accounts for approximately 90% to 93% of its composition. The remaining 7% to 10% is made up of polymer resins and pigments, which bind the quartz and give the stone its color and texture.

The manufacturing process of artificial quartz involves combining ground quartz with resin and pigments, which is then poured into molds to form slabs. These slabs are subjected to a vibrocompression process under vacuum, which involves vibration and pressure to compact the materials into a dense, non-porous surface. This process not only enhances the strength of the material but also ensures that it is consistent in color and pattern, unlike natural stone which can vary significantly from slab to slab.

The final product is a highly durable surface that resists scratches, stains, and corrosion, making it ideal for high-use areas like kitchen countertops and bathroom vanities. Additionally, because it is non-porous, artificial quartz does not harbor bacteria or viruses, making it a hygienic choice for both homes and public spaces.